Floor Building Panels

PRODUCT INFO

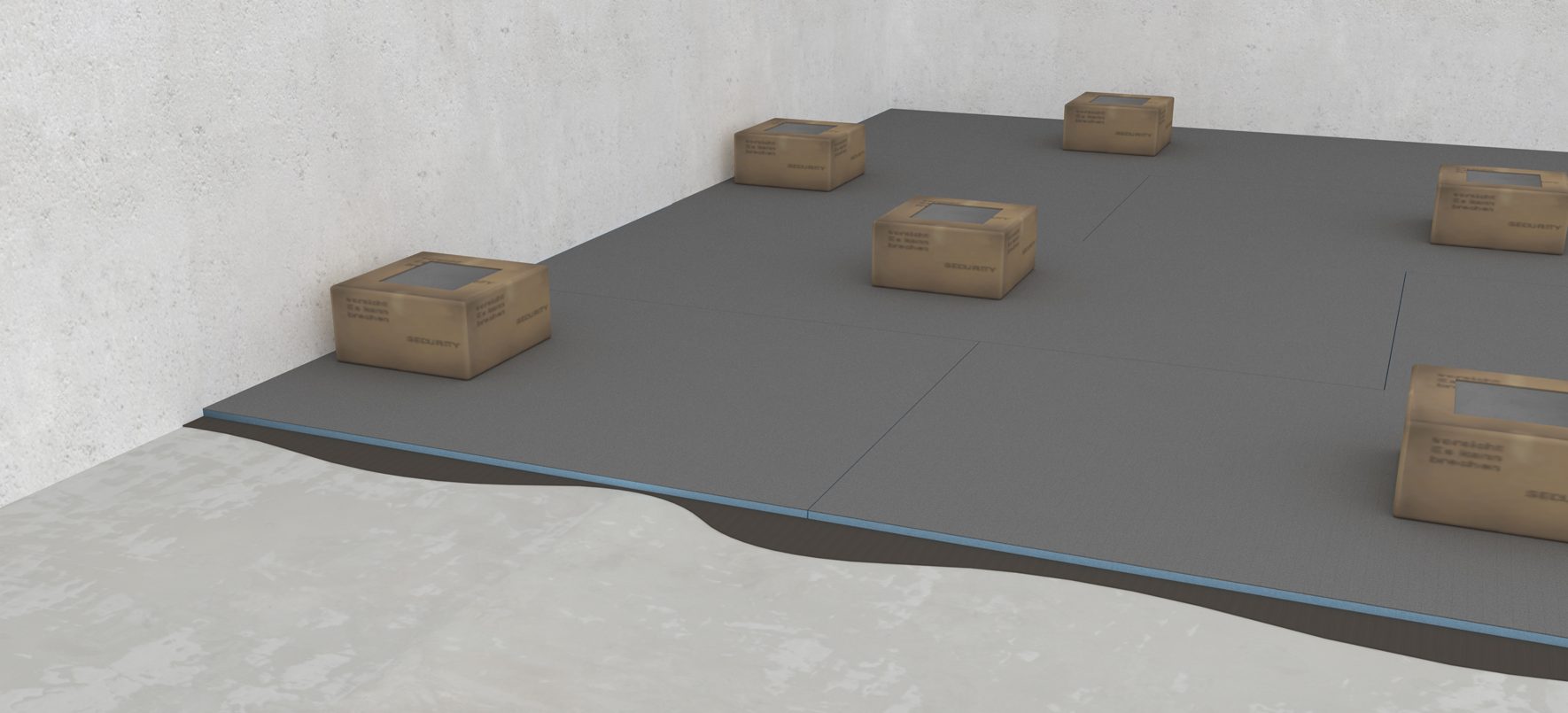

Whether for new construction or a renovation, a great variety of subfloor types need a tile underlayment prior to setting tile or stone.

KEY FEATURES

- Used in wet rooms, or where floor warming systems are used

- Ready for tiling upon installation

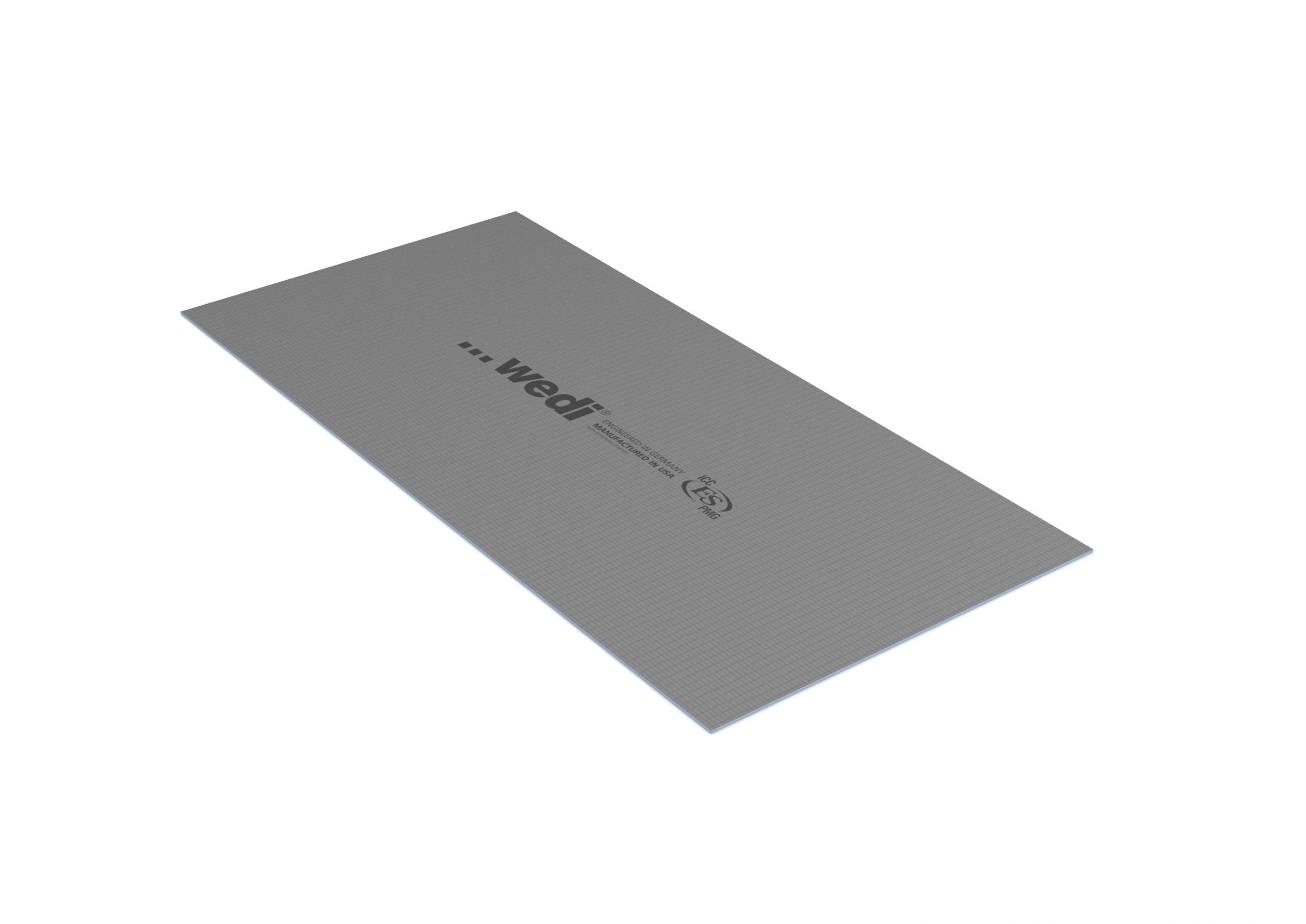

- 100% waterproof due to their extruded polystyrene (closed-cell) foam core

- Easy and clean to cut to size using a utility knife, circular saw, or handsaw

- Available in sizes and thicknesses that can accommodate different projects and applications

Ghost Accordion

Displays nothing

Building Panel Video

Installation Manual, Requirements/Limitations and Warranty

- wedi® Building Panel Installation Manual (Floor) – Download Here

- Limitations – Page 75 – Click Here

Product Approvals & Technical Performance Data

ICC PMG 1189 (for USA & Canada) – Page 74 – Click Here

Technical Performance Data – Page 73 – Click Here

Product Sizes

To determine the size and quantity of wedi Building Panels you will need for your shower, please follow the steps outlined below:

- Calculate the total area of the shower wall

- Multiply L x H of the wall. The height of each wall will be determined based on how high you plan to install the tile

- Add the calculated square footage of each wall together to determine the combined sum of all the shower walls

- Multiply the combined area of all shower walls by 1.15 to account for about 15% extra square feet of building panel for any waste cuts

- Divide the total area of the shower walls by the square foot area of the wedi building panels you plan to us4 (e.g. 4×5 ft. building panel = 20 square feet)

- A total shower wall area of 115 square feet divided by 20 square feet per building panel gives us a total of 5.75 building panels.

- Remember to always round up to the next whole building panel.

For product retail pricing, please see our Illustrated Retail Price List (USA) or Illustrated Retail Price List (Canada). These are also available in the downloads section.

Main Application

Dimensions

Unit

Item Number

Image

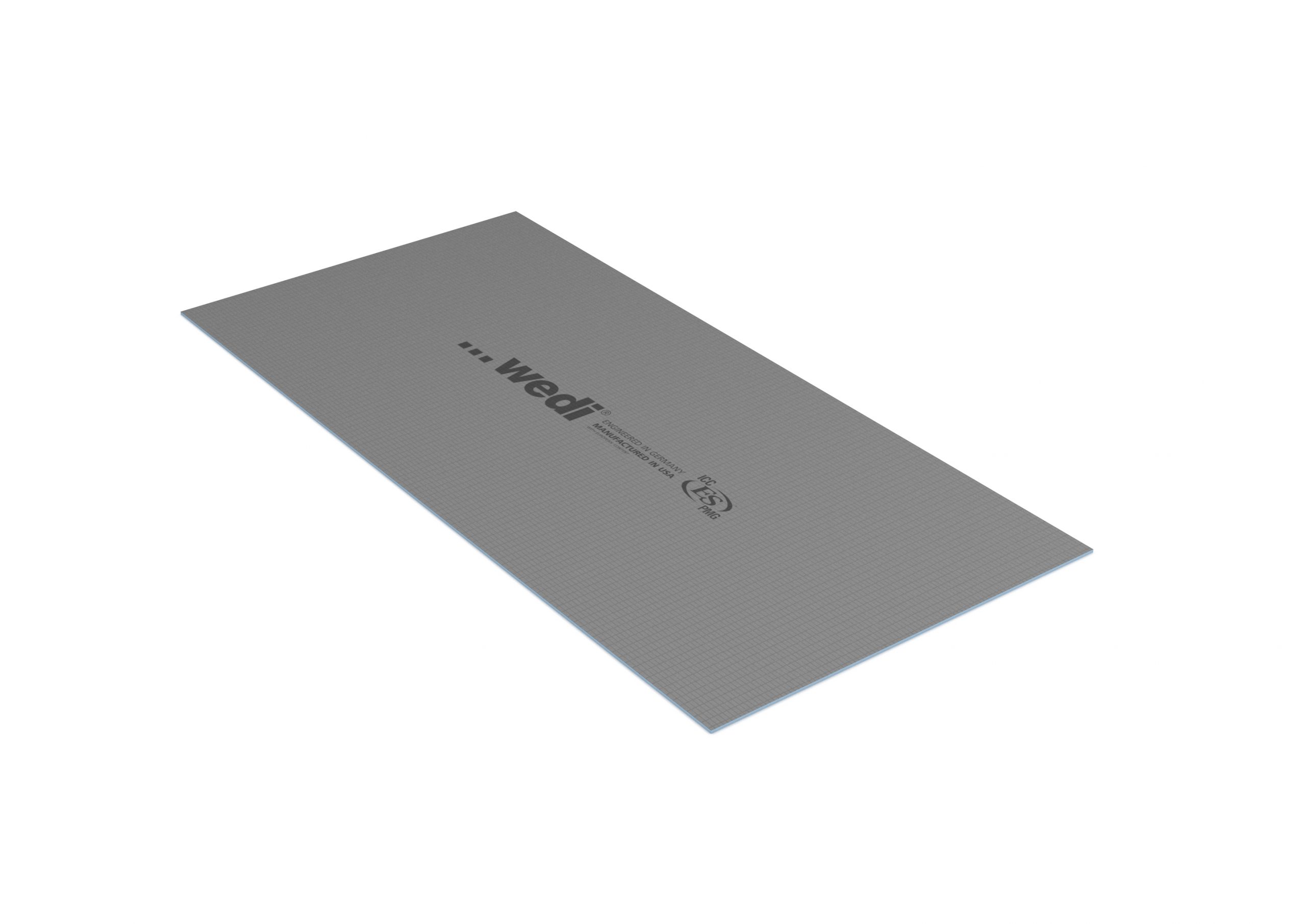

Backsplash, tub decks, floors, under mosaic strips in field tile designs

24 in. x 48 in. x 1/8 in.

10 sheets/box

US8000006

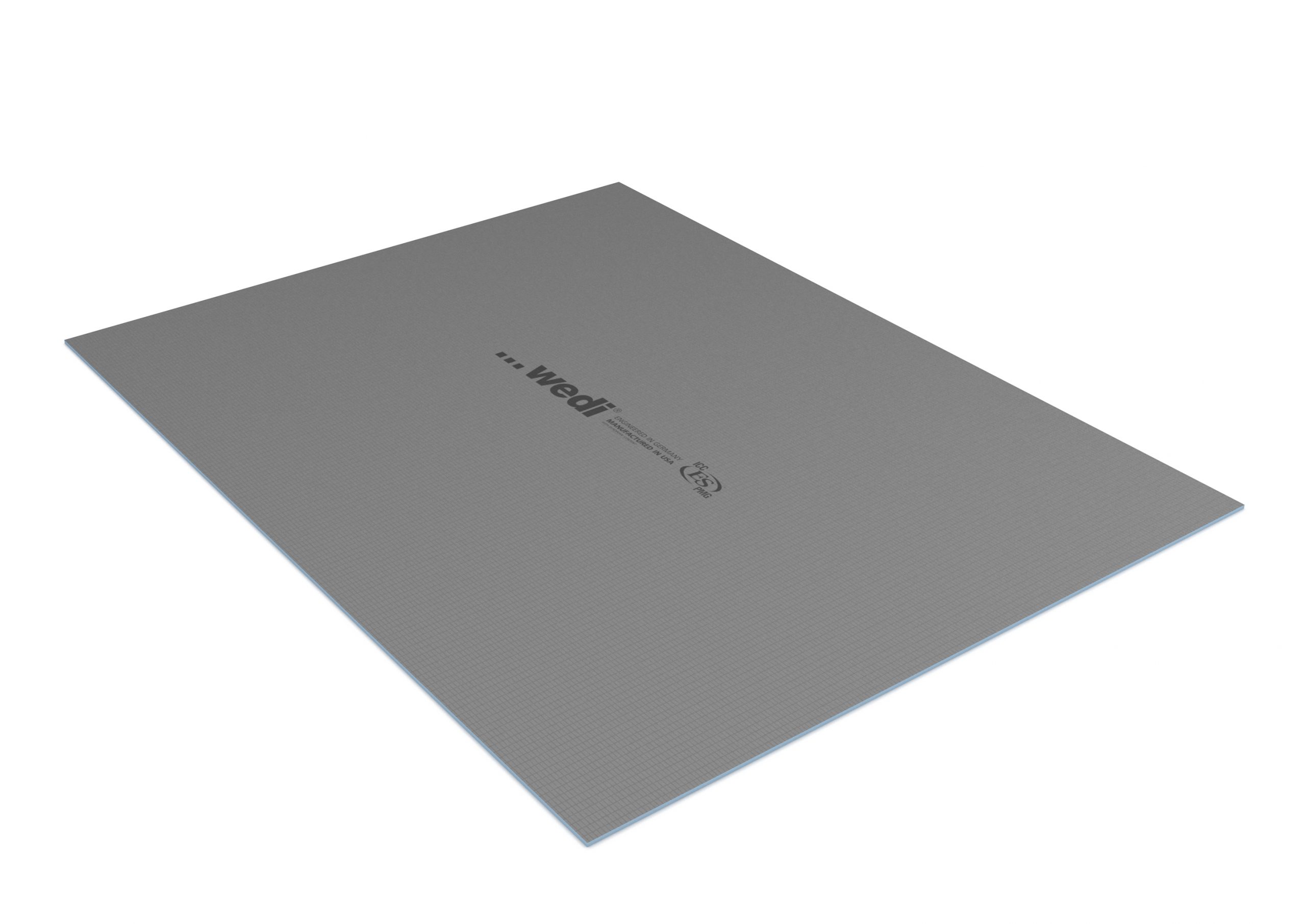

Tub decks, floors, with electric radiant heat

48 in. x 60 in. x 1/4 in.

25 sheets/pallet

US8000013

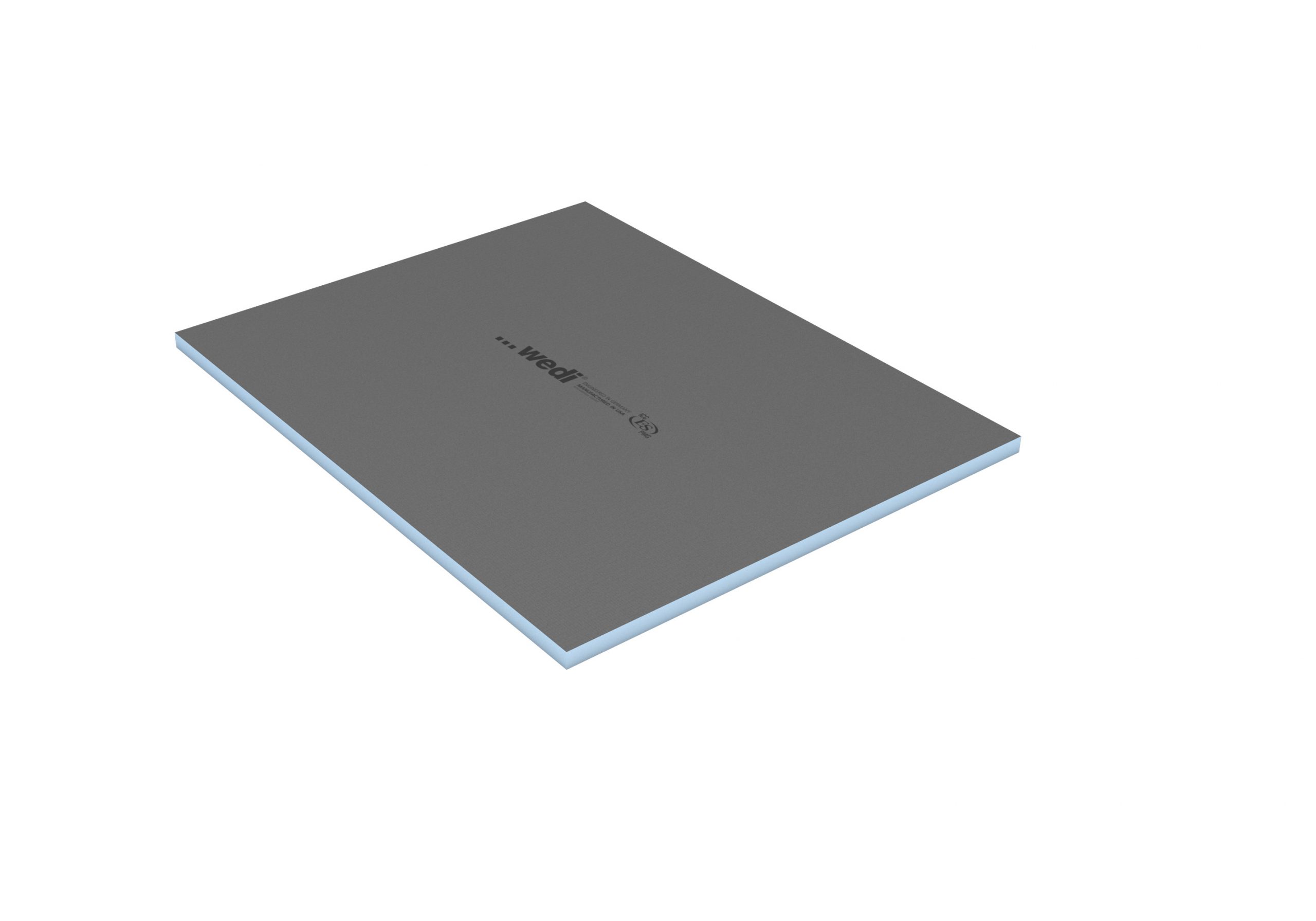

Floor panel, aligns with Fundo Curbless Shower Bases to create extension to bathroom floor

48 in. x 60 in. x 3/4 in.

4 sheets/box

US8000018

Constructing benches, floors to line up with Fundo Shower Bases into bathroom

48 in. x 60 in. x 1 1/2 in.

2 sheets/box

US8000019